House Wrap Sealing Tapes

Thermal barrier, higher energy bills, House wrap and 'the house as a system'

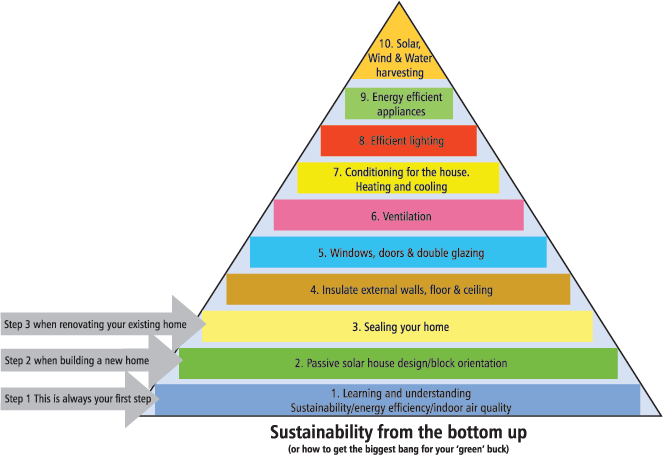

The assumption that a house is merely a collection and assembly of materials is a completely false one. For the last 30 years now, many Western countries have implemented the philosophy that a house should operate like a –sometimes fine tuned-engine, where each part, no matter how small, plays a crucial part in it's operation. This comes down to using the correct parts (or materials) and the correct installation.

If we relate the same engine philosophy to the construction of a house, one soon will find a myriad of discrepancies with the building products used and the way they are installed. Examples of this can be found all most daily in the media.

One of the most common discrepancies in housing can be found in the thermal barrier (insulation). Insulation products do perform as intended IF they are installed correctly. If installed incorrectly (compressed, gaps and cracks, missing batts), the thermal barrier will fail, causing higher energy bills, reduced comfort and possible mould issues for the occupants. (The engine doesn't run smoothly).

This is just one example of a discrepancy, but hundreds more can be found, mostly because of incorrect use of building product and/or installation.

House wrap has been used since probably the 1950's, starting with building paper and felt. These days there you'll find sophisticated house wraps under many different labels, however their function remains the same: allow moisture to leave the building cavity and prevent moisture (rain) from entering. So, the house wrap products are of high quality, what about it's installation?

To do it's job, house wrap should be continuous and without holes and gaps. This requires the use of tapes to seal the joints and any holes or gaps. If incorrect (cheap) tape is used, chances are the house wrap will fail in a short number of years. It's called delamination and happens when the tape comes off the wrap because of poor adhesion, temperature differences, or inadequate installation. Unfortunately this delamination takes place in the dark, behind the cladding and won't be discovered for many years, if ever.

So why do we install these external building systems using low-grade materials and applying poor work practices? The answer is two-fold: Firstly, the industry competes on prices and will always try to save money. Why using high quality tapes, when you won't be able to see the problem? Secondly: The level of education in the area of 'building envelop technology' and 'the house as a system' is minimal. Government does not promote quality education in sustainable building and the Code is slow to respond to new products/technologies.

In the end, it's the consumer who has to live with the final product.

Jan Brandjes

Brandjes Environmental Building Consultancy

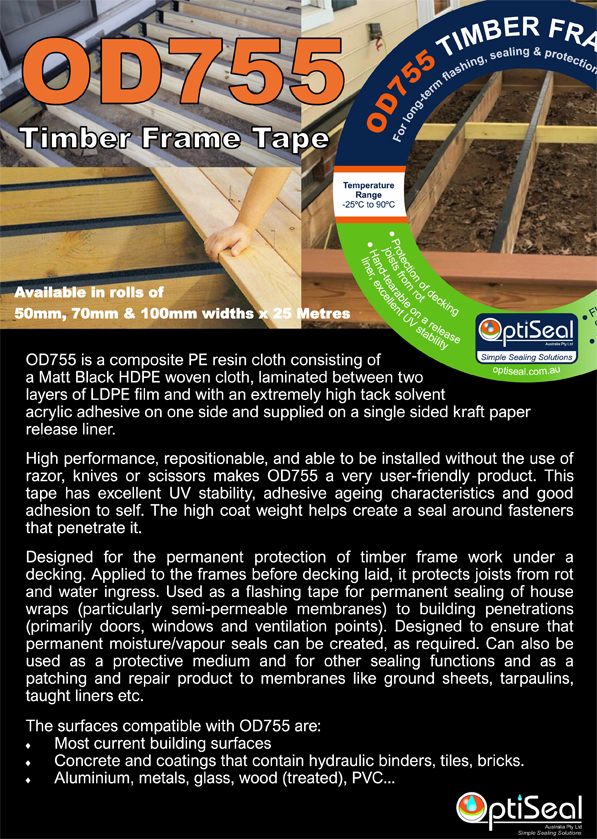

Timber Frame Tape

Designed for the permanent protection of timber frame work under decking, OD755 Timber Frame Tape is a composite PE resin cloth consisting of a Black Matt HDPE woven cloth, laminated between two layers of LDPE film and with an extremely high tack solvent acrylic adhesive on one side and supplied on a single sided kraft paper release liner.

Applied to the frames before decking is laid, it protects joists from rot and water ingress.

Used as a flashing tape for permanent sealing of house wraps (particularly semi-permeable membranes) to building penetrations primarly doors, windows and ventilation points. This tape has excellent UV stability, adhesive aging characteristics and good adhesion to itself.

Designed to ensure that permanent moisture/vapour seals can be created, as required. Can also be used as a protective medium and for other sealing functions as a patching and repair product to membranes like ground sheets, tarpaulins, taught liners etc.

The surfaces compatible with OD755 include:

- Most current building surfaces

- Concrete and coatings that contain hydraulic binders, tiles, bricks.

- Aluminiums, metals, glass, wood (treated), PVC...

View our brochure on Timber Frame Tapes

About Jan Brandjes

Jan Brandjes is a an independent building consultant who has written courses on sustainable building design and how to implement strategies to improve the thermal efficiency of buildings. He has extensive experience of working in climatic extremes, where achieving a comfortable indoor temperature is critical to a building's habitability. After 12 years of construction in Canada’s Far North, Jan migrated to Australia to start a new career in the building industry. Ending up in Sunbury, he constructed 3 demonstration project: The Sunbury Healthy House, The Eco Home and the Economical House. All three projects were developed to demonstrate the latest in energy efficiency, indoor air quality and affordable sustainable construction. For the past 4 years he has shared his 35 years experience in sustainability with many Master Builder students, and taught with a strong focus on the latest in building materials and technologies.

To Contact Jan Brandjes brandjesjan@gmail.com